Do you have worn or broken excavator steel tracks, track chains, track groups, or need steel tracks for sale for mini excavators? Having trouble keeping these parts on, especially on slopes or in soft conditions? It’s time for a new set of excavator steel tracks or track chains for your mini excavators and machinery from TKV.

TKV supplies links from 90mm pitch to 260mm pitch inclusive. These suit most makes and models of excavator, dozer, trencher, borer and much more. We also have steel tracks for mini excavators.

TKV is FASTEST and makes it EASIEST to get VALUE, LASTING or PREMIUM tracks & undercarriage parts on your machine.

The “TKV Promise Guarantee” is an expression of the confidence we have in our product. For example, to ensure only the highest quality levels, all bushings are subjected to a special induction heat treatment which hardens both the inside and outside surfaces. This thorough treatment significantly increases the service life of TKV’s excavator steel tracks, track chains and steel tracks for mini excavators.

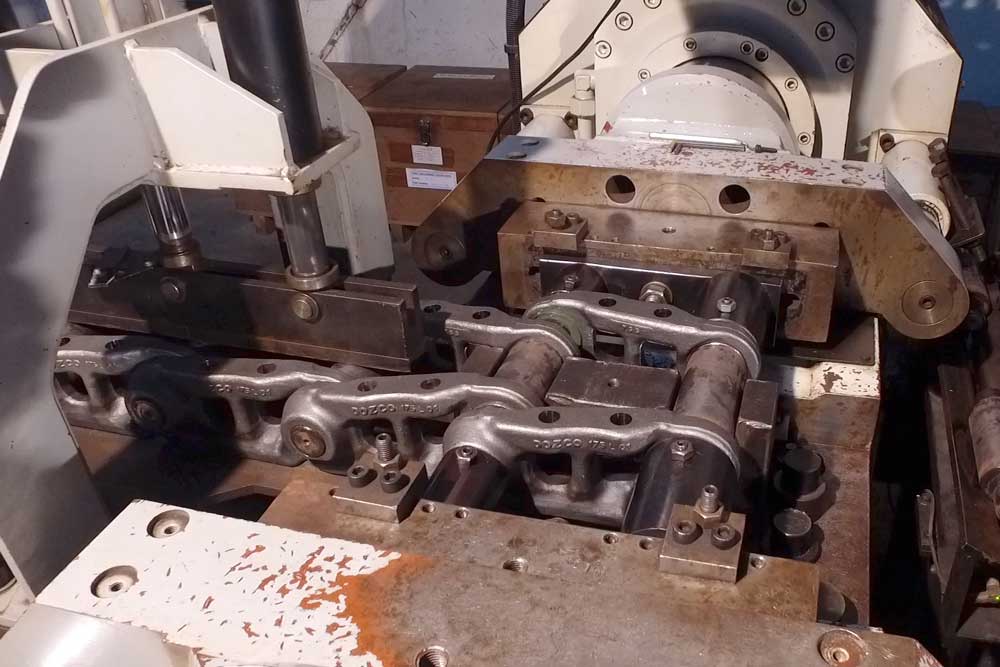

All our excavator steel tracks and track chains links are forged (not cast). They are subsequently processed on high-tech automated CNC machines. This guarantees a very high level of accuracy, thus better fitment. The carbon steel alloy selected ensures that the design does not become brittle through the heat treatment. Yet it retains a depth of hardening for long term wear characteristics.

To Keep Moving call 1300 65 11 43, use our Parts Finder or email us today to talk to one of our experts.