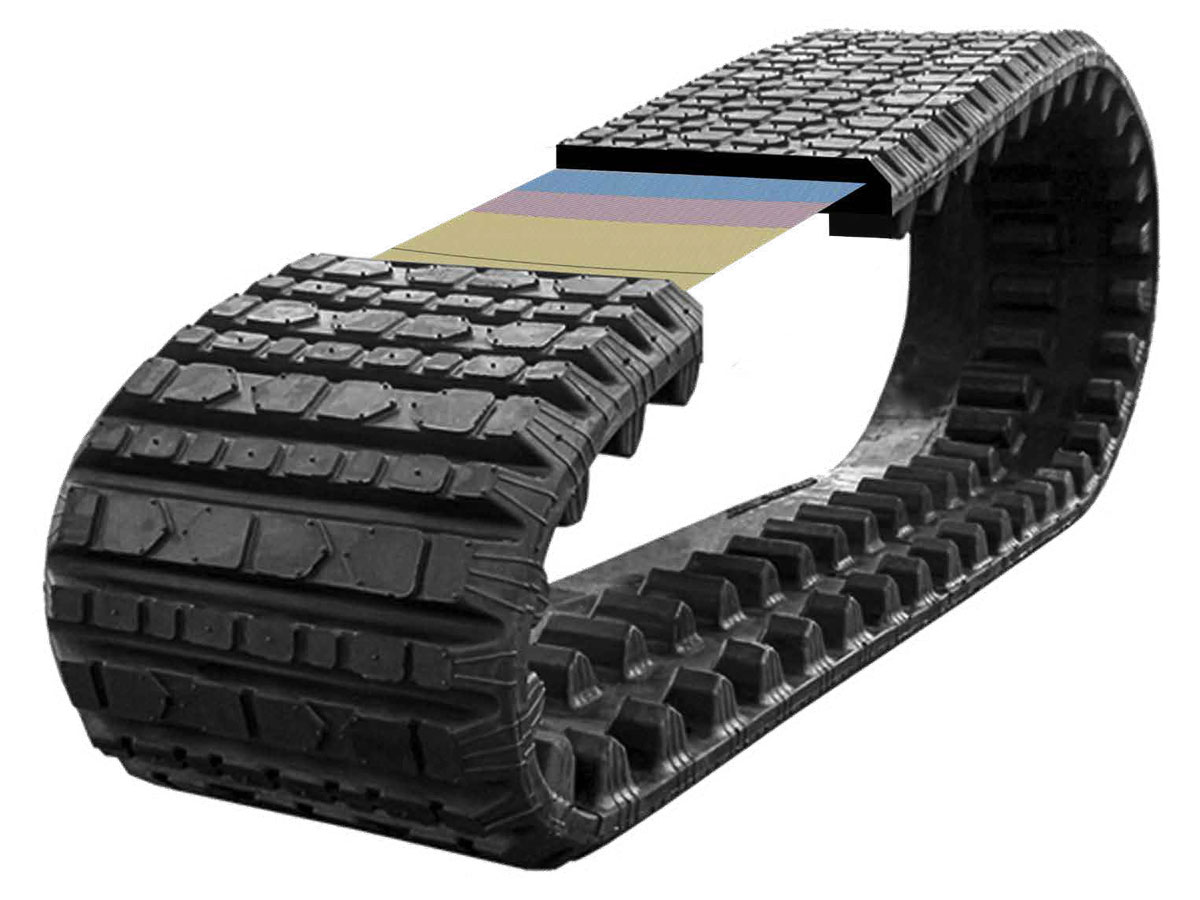

The MTL machine uses advanced core fibrous belting with molded rubber drive lugs, this requires high-quality materials and workmanship for manufacturing. TUFFTRAC exceeds these requirements, offering traction, flotation, and durability without excessive aggression on surfaces

TUFFTRAC MTL BENEFITS:

- Stronger: Optimised multiple fabric ply belting to provide maximum strength

- Last longer: Heavy duty increased carcass thickness designed to minimise puncture damage.

- Less down-time: Optimised drive lug geometry with shear resistant compounds to increase drive lug strength.

- Work lighter: Close tread pattern to help protect carcass and increase traction whilst minimising damage to the operating surface.

TRACK LOADER RUBBER TRACKS

There is no machine tougher on rubber tracks than a track loader. Capable of manoevering at high speed through the roughest of terrain, the multi-terrain track loader spends most of it’s time tracking.

TuffTrac MTL tracks are built to perform on Aussie worksites, with multi-layer rubber construction, heavy duty cables and the best performing materials.

MTL TRACKS

THE TUFFTRAC ADVANTAGE

FAST DELIVERY: Multiple stock locations

PEACE-OF-MIND: Expertise from years of hands on experience

FULL SERVICE: From supply only to on-site supply and fit we can help

AVAILABILITY: Largest rubber track stock holdings in Australia – more than 280 individual sizes in stock at any time.

TUFFTRAC rubber tracks are backed up with a genuine TKV Promise Guarantee providing guaranteed wear life. TUFFTRAC – the Aussie contractor’s choice.

TREAD DESIGNS

Matching OEM treads, and with years of testing this tread pattern has proven to increase durability when compared to other tread designs, by reducing the force on the weak and higher stress points.

HIGH TENSILE FABRIC REINFORCING

The track is formed around a central high tensile fabric core, providing unparalleled strength in this type of track.

RUBBER COMPOUND

The rubber compound is unique and contains virgin rubber, carbon black, and many other compounds and materials to aid in the strength and durability of these rubber tracks. This formula also significantly minimises the chunking and cut damage caused by sharp objects. This increases the lifespan of the track and reduces the chances of premature breakage.

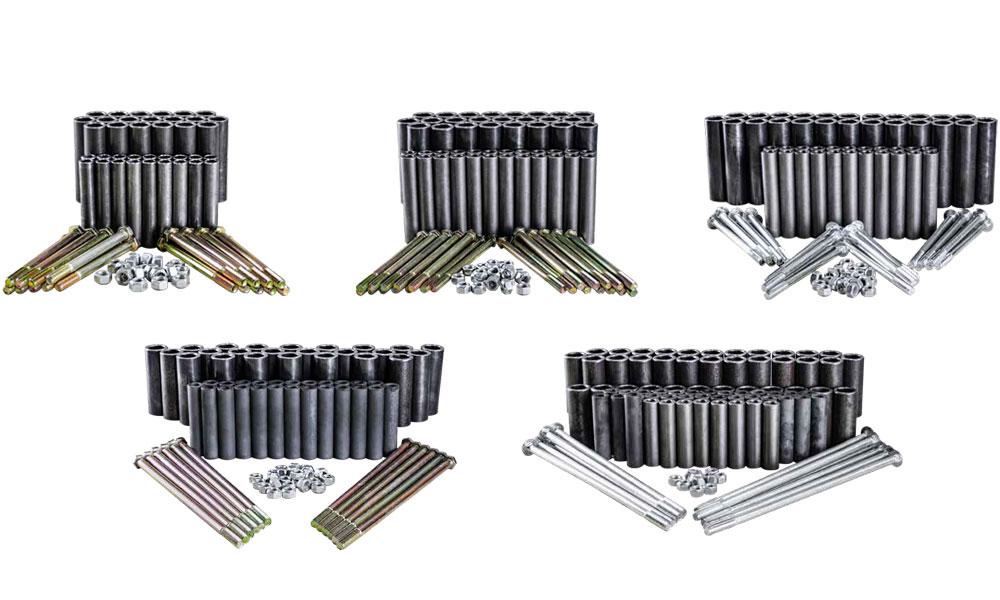

UNDERCARRIAGE

The TuffPart MTL Undercarriage series covers a comprehensive range of components to fit almost every make and model of Multi-Terrain Track Loader.

At TKV we take pride in the quality of our product – that’s why we guarantee you the best value for money and maximum wear-life.

This combined with leading edge heat treatment techniques, TuffPart offers the ultimate wear resistance in the worst operating conditions.

When only the toughest will do, choose TuffPart undercarriage parts for your Multi-Terrain Track Loader.

For more info DOWNLOAD the MTL Brochure now.