TKV offers the most extensive selection of excavator track rollers, carrier rollers (both bottom and top), idler assemblies (IDLER ASSY), sprockets, and sprocket segments in Australia.

At TKV we make it FAST and EASY to keep your machinery moving.

Need your track rollers or parts in a hurry? Just give us a ring at 1300 65 11 43, or use our handy Parts Finder tool to quickly locate the perfect fit for your machine.

Our products are known for their exceptional longevity, backed by the TKV Promise Guarantee, which goes beyond standard manufacturers warranties.

We support a wide range of brands, including Airman, ASV, Bobcat, Case, Case IH, CAT, CAT Challenger, Claas, Doosan, Hitachi, Hyundai, IHI, JCB, John Deere, Kobelco, Komatsu, Kubota, New Holland, Sumitomo, Takeuchi, Terex, Vermeer, Versatile, Volvo, Yanmar, and many others.

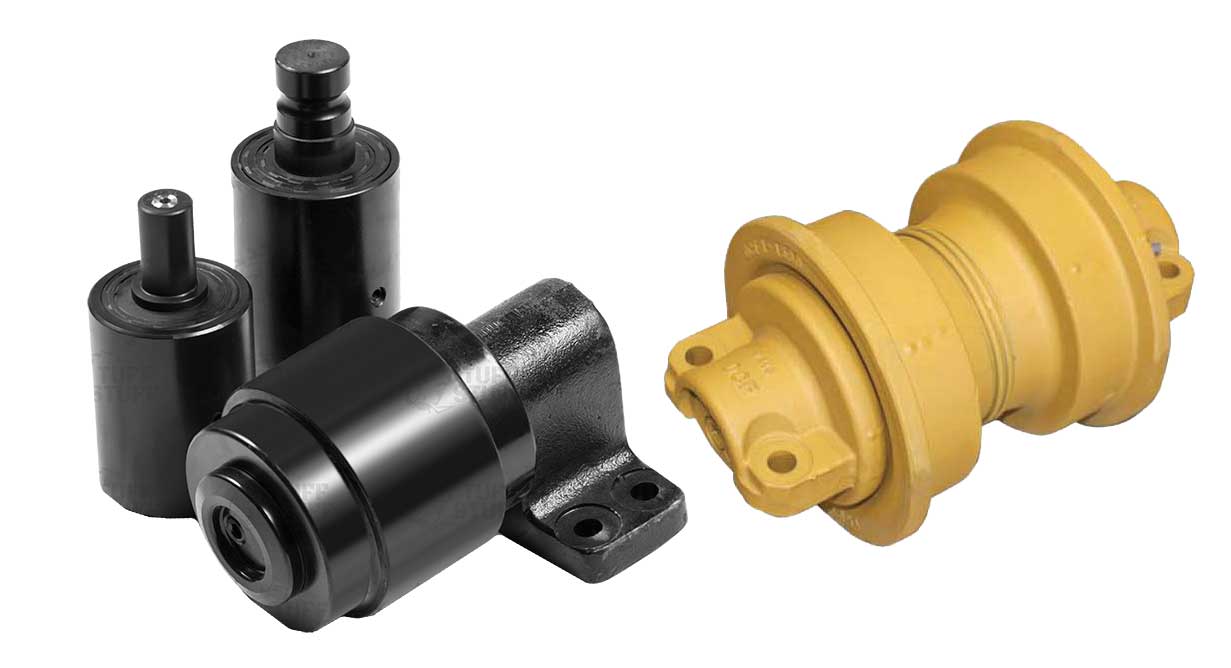

Sprockets & sprocket segments

TKV offers a wide range of sprockets which are designed to fit on both tracked Loaders and excavators, spanning from 1 to 30 tonne.

Our sprockets are precisely crafted from steel alloys, utilizing either casting or forging methods. Afterward, they undergo a precise heat treatment process and machining to meet exacting standards. The composition of the steel alloy is of paramount importance, as an insufficient amount of carbon can render the steel brittle during the hardening process. Moreover, merely surface hardening the sprocket leads to rapid wear. To ensure the correct depth of hardening, our sprocket teeth undergo induction hardening, guaranteeing durability and performance.

To discuss your track and undercarriage needs call 1300 65 11 43, use our Parts Finder or email us.