You scratch your head, jump out of the cab into the squelching mud and DAMN!! You’ve broken a track.

We’ve all been there haven’t we. This is more than just a passing frustration and a bit of a bother; it is potentially expensive and seriously inconveniencing.

Track failure, it always happens at the most inappropriate time and inappropriate place. So how can you spot it coming and act ahead of time? Below are five sure signs to look out for that can indicate failure is imminent.

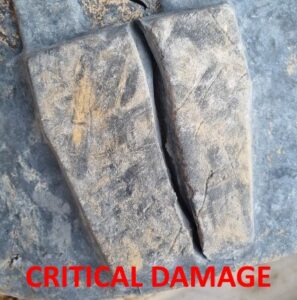

Crack External

External cracks and cuts are very common around the track, the skill is to be able to identify if the damage is critical or purely cosmetic.

As a rough rule of thumb, cracks and cuts in the tread bars are typically cosmetic and result from damage, it’s the cracks and cuts down on the carcass of the track that can presage problems.

To assess the seriousness of this type of damage, track the cut/crack till it is around the idler and the damage should open up as the track curves around. If you can see the steel cables clearly at the base of the damage this is a sure sign that failure is not too far away. Water ingress results in the cables rusting and ultimately failing.

Crack Internal

Rubber cracking internally is less common than tread side cracking, however it tends to more often be serious. Of particular concern is cracking around the steel core bars which carry the driving force of the sprocket and the weight of the machine from the rollers. This cracking can be caused by a lot of factors including over tensioned tracks, worn sprockets, debris caught in tracks or poor manufacture, the nett result however is the same. If water penetrates the tracks between the rubber and the steel core bars rust forms breaking the bond and ultimately resulting in the core bars being spat out and……….failure.

Exposed Cables – Worn Out

This one is pretty self-explanatory – your tracks are finished. Whether due to abuse, poor rubber or just lots of hard work, the nett result is you are due for a new set of tracks. Persisting in this condition is only going to lead to tears.

Cable Failure

This one can be hard to predict. The cables wound around internally in the track are what provides the tensile strength of the track and stop it stretching. Once cables fail, nothing good can happen. At best you will throw a track, but very likely your track will break in two. As the cables are made from high tensile steel, metal fatigue is the most common cause of this failure and it can happen suddenly. However, if you do see a number of cables poking out of your track, its time to stop and assess the situation. A single cable end can come free, called “wild wires” this is not normally a problem except for the looks, but if multiple cables in the same location come free, you got troubles heading your way!!

Loosing Core Bars

As per cable failure above, this problem is pretty much terminal. You can often limp your machine banging and clunking back to a safe place for new tracks, but once you lose the first core bar, the next is going to follow close behind. Before long you’ll be stuck, so I’d highly suggest calling TKV soon as this occurs.